Cold Peel DTF Transfers: Precision Prints with Superior Durability

When you need flawless prints that stand the test of time, our Cold Peel DTF Transfers deliver. Engineered for clarity, color accuracy, and resilience, these transfers are perfect for producing sharp, detailed artwork on all types of garments. Cold peel technology ensures a smoother finish and better wash durability.

Cold Peel DTF Transfers for Quality

From the first transfer to the last, you’ll notice the difference in quality and performance.

Reliable Cold Peel DTF Transfers

No matter your vision, Cold Peel DTF is the perfect choice for detailed graphics, logos, and full-color artwork.

Cold Peel vs. Hot Peel: A Quick Comparison

- Speed vs. Detail: Because you don’t have to wait, hot peel is faster for production – great for very high-volume jobs where every second counts. However, cold peel is better for complex and intricate designs.

- Durability: While both methods produce durable prints, Cold Peel tends to have superior durability and wash resistance.

- Peel Timing: Cold Peel transfers are removed after they cool down completely, requiring a short wait time. Hot Peel transfers are peeled immediately while still hot right after pressing

DTF Cold Peel Instructions

Using DTF Cold Peel transfer film is straightforward. Here are the Cold Peel Transfer Instructions:

1. Position on Garment: Place the garment (t-shirt, hoodie, etc.) on the heat press and pre-press it for 5 seconds to remove any moisture and wrinkles.

2. Heat Press the Transfer: Close your heat press and apply firm, even pressure. Press at 320 °F for 15 seconds.

3. Cool Down (Cold Peel): This step is what makes it a cold peel transfer. After pressing, carefully remove the garment from the press and let it cool down completely

4. Peel Off the Film: Once the transfer is completely cool, slowly peel the film away from the garment.

5. Post-Press: For the ultimate finish and durability, you can do a quick post-press. Remove the used film and cover the transferred design on the garment with a parchment paper or Teflon sheet. Press it again for 5-10 seconds at the same temperature.

Why Choose DTF Cold Peel Transfer Film?

- Broad Fabric Compatibility: One of main advantages is versatility. Nearly any cloth cotton, polyester, poly-blends, denim, canvas, and more can be used with cold peel transfers. Light or dark garments, thick or thin fabrics, this film handles them all. This means you can fulfill a wide range of orders (t-shirts, hoodies, tote bags, etc.) with one reliable product.

- Easy Handling & Forgiving Application: Cold peel is beginner-friendly and stress-free. Because you wait for the print to cool before peeling, there’s no rush or tricky timing under heat. This forgiving nature reduces errors

- High Production Performance: Even if cold peel requires a cooling step, it’s still a high-output choice for businesses. You can print in batches, set them aside to cool, and maintain a fast workflow.

Ready to Get you Cold Peel DTF Transfers?

Ready to take your apparel printing to the next level? Whether you're a small business owner, apparel brand, or print shop, ourCold Peel DTF Transfersdeliver the flawless, long-lasting results your customers expect. With vibrant color, sharp detail, and smooth matte finishes, these transfers are perfect for t-shirts, hoodies, bags, and more. Get your Cold Peel DTF Transfers atdtftransfersnow.com!

FAQS

What is DTF Cold Peel, exactly?

What is DTF Cold Peel, exactly?

What fabrics does it work on?

What fabrics does it work on?

Does using cold peel slow down my production?

Does using cold peel slow down my production?

Cold peel vs. hot peel – which is better for my business?

Cold peel vs. hot peel – which is better for my business?

Special products

-

Sale

Glitter DTF Transfers

Regular price From $12.60Regular price$14.00Sale Sale price From $12.60 -

Sale NEW

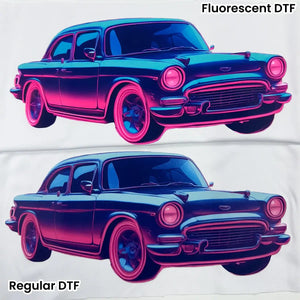

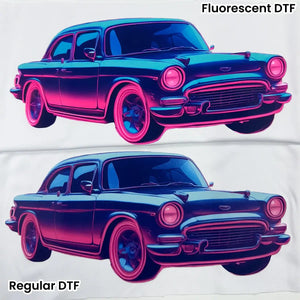

Fluorescent DTF Transfers - Neon Colors

Regular price From $9.99Regular price$10.80Sale Sale price From $9.99 -

Sale

Ultra 9 Color ORGB DTF Transfers

Regular price From $7.20Regular price$8.00Sale Sale price From $7.20 -

Sale

Glow In The Dark DTF Transfers

Regular price From $12.60Regular price$14.00Sale Sale price From $12.60